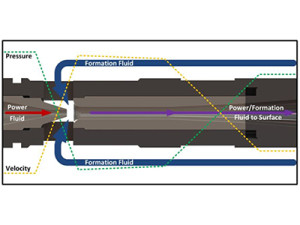

The jet pump technology has been around for decades. It is a tried and tested technology that is utilized in many well configurations to create artificial lift, which raises liquids from low-pressure conditions in reservoirs or formations. The principals engaged are simple if you understand physics as they relate to the Venturi effect. With this principle, system fluid pressure is converted into a jet stream of high energy. This creates a low-pressure condition at the pump intake.

The jet pump technology has been around for decades. It is a tried and tested technology that is utilized in many well configurations to create artificial lift, which raises liquids from low-pressure conditions in reservoirs or formations. The principals engaged are simple if you understand physics as they relate to the Venturi effect. With this principle, system fluid pressure is converted into a jet stream of high energy. This creates a low-pressure condition at the pump intake.

New Generation of Hydraulic Jet Pumps

Recent developments have made a new generation of hydraulic jet pumps a viable solution for a wider range of wells while requiring much less maintenance for the end user.

The benefits of the jet pump are:

- No moving parts down-hole

- Ability to produce sands and solids

- No gas locking

- The power fluid can be treated with corrosion and scale inhibitors

- Ease of optimization with software

- Production rates can be changed by adjusting injection pressure and rate

- Capability of producing high volumes of fluid and ease of serviceability because nozzle and throat can be hydraulically retrieved with no rig or wire line.

| Problem | Impact | Solution |

| Wells producing sand, | PCP torque issues | Jet pumps have no moving parts and thus can handle solids and there is no torque issues |

| Wells producing clays | Pumping issues

|

Jet pumps have no moving parts and thus can handle solids and there is no torque issues |

| Wells producing solids | Pumping issues

|

Jet pumps have no moving parts and thus can handle solids and there is no torque issues |

| Tubing and rod wear in deviated wells | Loss production,

Well intervention and workover |

With no moving parts there is no wear on rods and tubing compared to pumps with downhole moving parts |

| Well intervention / service rigs | Financial impact

Lost production Scheduling issues |

With no moving parts there is no wear on rods and tubing compared to pumps with downhole moving parts |